A case study from Technikgruppe

Due to mostly unpredictable fluctuation in waste input quality, it is not easy to keep the combustion process in waste to energy plants stable enough. In most cases, classic controllers and conventional control strategies cannot guarantee the stability of steam production, and therefore the total possible combustion capacity (e.g. 110%) cannot be used.

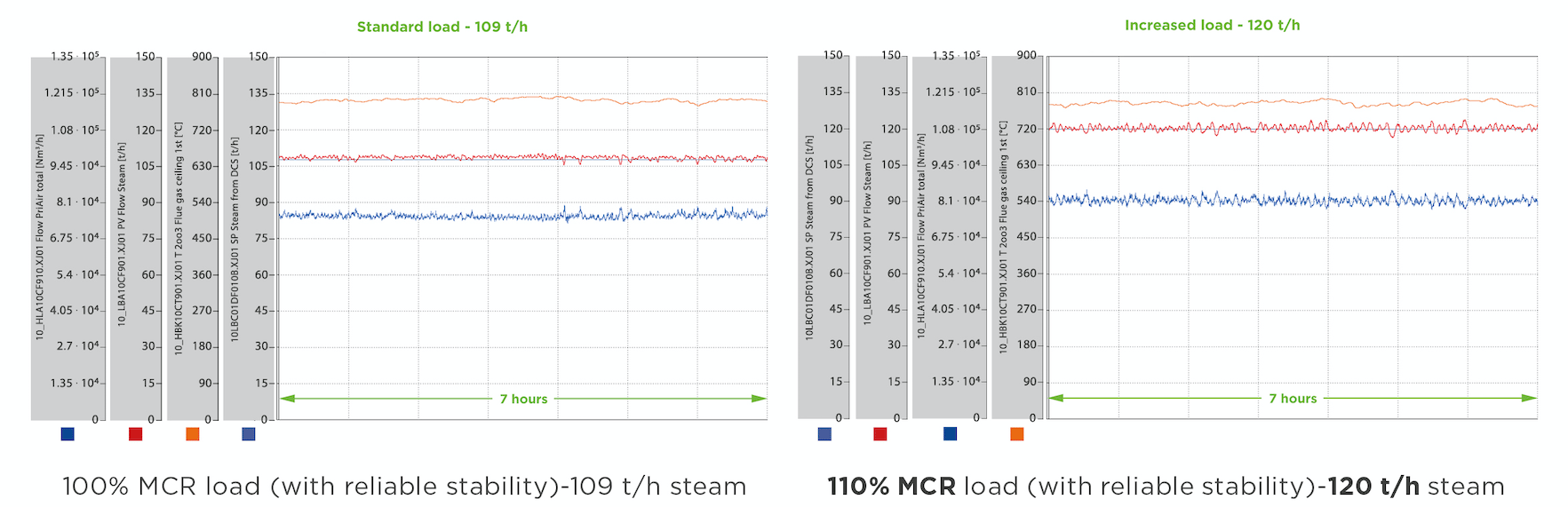

But Technikgruppe’s WiC Combustion Manager contains very complex and powerful algorithms that ensure reliable steam generation stability over an extremely large range of calorific value fluctuations. As a result, steam generation may approach the system’s design limit due to the lack of overshoot. Of course, a maximum continuous rating (MCR) of 110% is not possible in all cases, but mainly depends on the manufacture and the design reserves for expected fluctuations.

A case of such an improvement is shown in the accompanying diagrams. In this special case, no hardware changes were necessary, and the steam generation was very stable even at 110% MCR. The combustion improvement was carried out 100% automatically.

Please sign in or register for FREE

If you are a registered user on Energy from Waste Network, please sign in