ETS, Plastics and EfW: turning a new cost into a manageable system

Europe’s Emissions Trading System is moving closer to the EFW industry. Since 2024, incinerators must monitor, report and verify their CO₂ emissions, although they do not yet surrender allowances. The European Commission will report by 31 July 2026 on full inclusion, with 2028 discussed as an earliest start. For operators, the direction is clear. Prepare now.

Where the cost comes from

Only fossil-based CO₂ is in scope for ETS. Emissions from the biogenic fraction of waste count as zero, provided sustainability criteria are met. In simple terms, plastics drive the liability while food, paper, wood and other biogenic materials do not.

Traditionally, the fossil share of mixed waste is determined with laboratory methods. These are robust for compliance but periodic, sample-based and slow. They do not give supplier-level accountability or day-to-day control.

The operational challenge for EfW sites

As ETS moves closer, operators face three linked questions:

- What fossil content is arriving at my gate today

- Which suppliers are responsible for it

- How do I reflect the associated cost in gate fees and contracts, fairly and defensibly

Without high-frequency insight, plants risk an uplift in gate fees that penalises good suppliers and fails to change behaviour. With precise data by truck and supplier, operators can renegotiate terms, apply surcharges or incentives, and evidence decisions. Contractual and national rules apply, but accurate allocation is the foundation for any pass-through.

How AI closes the gap

Artificial intelligence now makes it practical to measure composition, calorific value and biogenic indicators for every delivery, not just occasional samples.

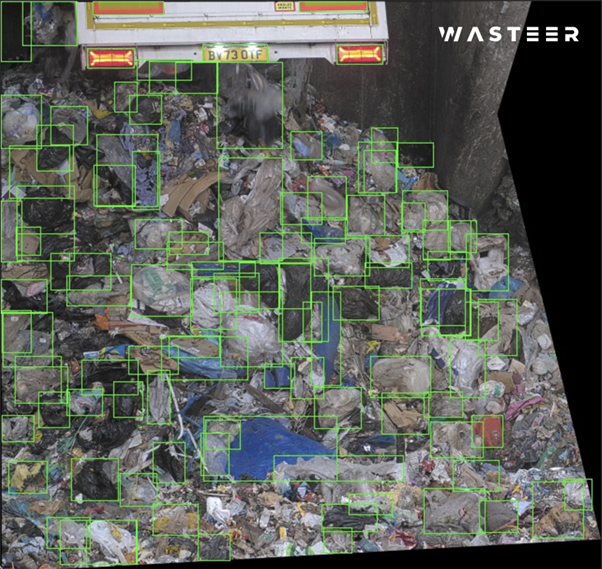

Wasteer is a startup specialised in high-volume waste analysis. We work with 22 EfW plants across six countries and analyse more than seven million tonnes of waste per year. Our system uses cameras that observe the tipping floor and the bunker. Computer vision identifies material categories, estimates composition, and links each observation to licence plates and gates. It also flags contaminants and emission-risk items. From these detections, our models estimate calorific value per load and infer the biogenic versus fossil share at the delivery level, which is what matters for operations and commercial decisions.

What this delivers for ETS readiness:

- Per-truck composition and fossil indicators. See the plastic share for each supplier by day, week and contract period.

- Gate-fee alignment. Allocate ETS-related costs to the sources that drive them, subject to your contracts and local regulation.

- Continuous verification layer. Use the high-frequency stream to target and schedule compliance-grade lab tests, reducing uncertainty and cost. Lab results remain the reference for formal reporting, while AI provides coverage between samples.

- Operational stability. Early warnings for items that trigger emission spikes or incidents, plus bunker views that support safe, steady feeding.

Why frequency matters

Moving from monthly or quarterly sampling to per-delivery analytics changes behaviour. Suppliers see the impact of their loads in days, not months. Contracts can include clear targets for fossil content with data to back them up. Plants protect margin when plastics rise and reward suppliers who improve. This is how an unfriendly new cost becomes a lever for quality.

Discuss it live at the Operational Optimisation conference

We will be on site throughout the event. Join our CEO and Founder, Benedict Von Spankeren, at 14.00 on Day 2 for a focused session on contaminant detection, composition analysis and ETS readiness for EfW plants. Drop by the talk to discuss your use case, email us at hendrik.depaepe@wasteer.com, or connect on LinkedIn: https://de.linkedin.com/company/wasteer.

Please sign in or register for FREE

If you are a registered user on Energy from Waste Network, please sign in