Single-Source strength: How British manufacturing with global reach supports Energy-from-waste

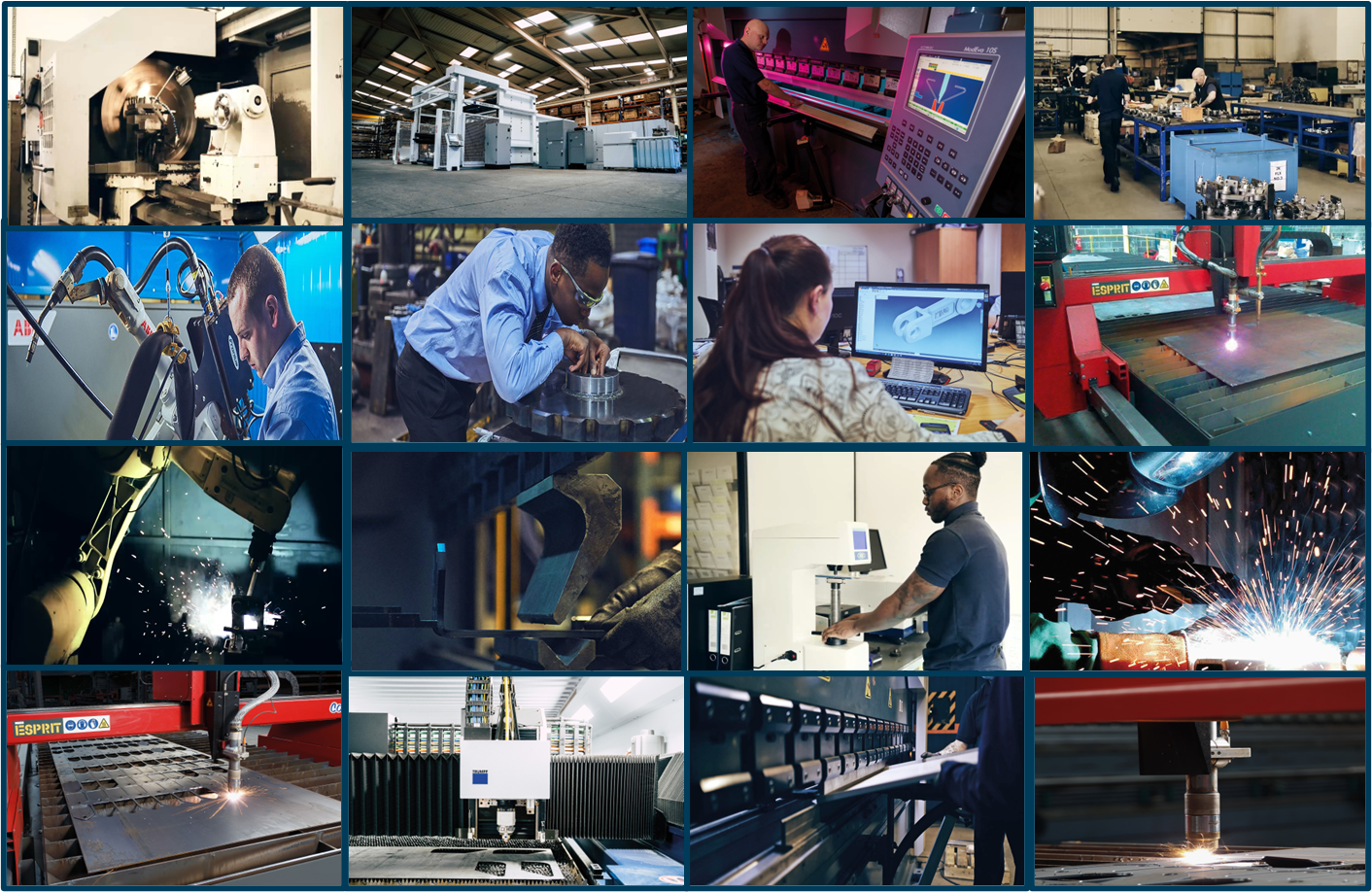

Poster image: John King Site.

Energy-from-Waste’s growing importance

Energy-from-Waste has become one of the most efficient ways to tackle two challenges at once: reducing landfill and generating renewable energy. Across the UK and worldwide, EfW plants turn hundreds of thousands of tonnes of residual waste into reliable sources of power each year.

For the industry, the opportunity is clear. But for operators, the reality is tough. EfW plants work in some of the harshest industrial environments. Chains, conveyors, sprockets, valves, and fabrications are under constant strain from high heat, abrasive ash, and corrosive atmospheres. When a plant stops, the costs add up quickly. Keeping waste moving is the only way to keep energy flowing.

That’s why the choice of supply partner matters. EfW plants need equipment designed for the job and a manufacturer who can supply product engineering, technical support, and on-site service.

The challenges inside EfW plants

EfW plants are designed to run around the clock, but the waste they process is anything but uniform. Mixed material streams can contain glass, metal, grit, and other contaminants that wear parts down faster than expected. Ash handling systems are particularly unforgiving, with fine abrasives prematurely wearing chains and components if the correct materials are not selected.

The main challenges operators face include:

- Increased wear rates on conveyors, chains, and sprockets.

- High heat exposure, especially around combustion grates and ash zones.

- Corrosion, where systems come into contact with flue gas or wet ash, containing sulphides and other corrosive elements.

- Limited maintenance windows, meaning parts must be replaced quickly and correctly.

- Spares availability, which can be slow with many providers sourcing from overseas.

When these problems aren’t managed, downtime follows. Every breakdown means wasted hours, higher running costs, and pressure on already tight operating margins.

Why single-source supply matters

Many plants work with multiple suppliers, one for chains, another for sprockets, another for fabrications, and yet another for servicing. In practice, this can create as many problems as it solves:

- Parts from different sources don’t always work together, causing uneven wear.

- Sourcing delays from several suppliers can extend downtime.

- Responsibility for failures is harder to manage.

A single-source supplier takes away that risk. With one partner covering design, manufacture, installation, and service, everything is made to work as a system. Spares are consistent, delivery is quicker, and there is one point of accountability.

How John King delivers the single-source model

John King Group is one of the few companies able to offer this complete package. Founded more than 100 years ago in Yorkshire, the business has grown from a traditional chain manufacturer into a global supplier of materials handling services, with operations on four continents. What hasn’t changed is its commitment to manufacturing strength in the UK, backed by worldwide reach.

At its headquarters in Sherburn-in-Elmet, the company designs and manufactures conveyor and elevator chains, matched sprockets, complete conveyor systems, valves, wear parts, precision-engineered components, and heat-resistant steels. All work is carried out to ISO 9001:2015 standards, with in-house metallurgy and heat treatment facilities ensuring full quality control.

Alongside this production capability, John King operates a dedicated site service division. Engineers provide inspections, condition monitoring, planned maintenance, emergency repairs, refurbishment and retrofitting, and installation of new equipment. Safe systems of work are central to every project. All activities are delivered under internationally recognised standards, with a strong focus on health and safety (ISO 45001) and environmental management (ISO 14001).

The British manufacturing advantage with global reach

British engineering is trusted worldwide for its precision and quality. For EfW operators, sourcing from John King means benefitting from that tradition while also accessing global service. With core production in the UK, the company is not reliant on complex overseas supply lines, allowing for quicker delivery of spare parts and greater resilience in times of disruption.

This local manufacturing base also strengthens sustainability. UK production and shorter supply routes reduce carbon impact while ensuring full traceability across the supply chain. At the same time, choosing John King supports British jobs, apprenticeships, and engineering skills, while global facilities in Europe, North America, Asia, and Africa provide local service with UK quality standards.

Equipment built for EfW

EfW is not an industry where standard parts last. Every John King product is designed with the specific challenges of the sector in mind. Chains are produced from selected alloys and heat-treated for durability. Split sprockets and attachments are designed to minimise downtime and reduce maintenance costs. Heat-resistant alloys and irons are proven in combustion plants, while custom fabrications include ash hoppers, precipitator conveyors, transfer chutes and more.

Crucially, the equipment is designed with maintenance in mind.

Looking ahead – EfW’s future and John King’s role

The Energy-from-Waste sector is expanding rapidly. In the UK, EfW already powers hundreds of thousands of homes, while in Europe, North America, and Asia, major new facilities are under construction. As landfill diversion targets tighten and demand for renewable power grows, EfW’s role will only increase.

John King is investing to support that future. The company is developing new alloys and treatments to extend service intervals, improved conveyor designs for quicker and safer maintenance, and monitoring technology to give operators early warning of wear. Just as importantly, it continues to strengthen its commitment to safer working practices through ISO 45001 and to reducing environmental impact through ISO 14001.

A partner for the long term

EfW plants are built to run for decades, but to achieve that they need supply partners who understand the industry inside out. Operators require equipment designed for the job, built to last, and supported for the life of the plant.

John King Group offers exactly that. With over a century of British manufacturing heritage, complete in-house capability, and a presence across four continents, the Group delivers equipment and service trusted in EfW plants worldwide. Every chain, sprocket, valve, and conveyor system is made to exacting standards, backed by a team who can design it, build it, install it, and keep it running all under ISO 9001, ISO 14001, and ISO 45001 accreditation.

As EfW continues to grow in importance, John King is committed to keeping waste moving, energy flowing, and plants performing.

Please sign in or register for FREE

If you are a registered user on Energy from Waste Network, please sign in