Wasteer: Closing the Knowledge Gap in Energy from Waste Plants

Energy-from-Waste (EfW) plants are vital to advancing sustainability, but they increasingly face practical challenges that disrupt operations. Issues such as rising levels of contaminants in waste streams, explosions caused by laughing gas bottles, and unplanned plant shutdowns highlight the need for better oversight. Without clear visibility into waste streams, identifying risks, optimising processes, and maximising efficiency become significantly harder. Gaining deeper insights is essential to addressing these challenges and unlocking the full potential of EfW operations.

Understanding the Challenges

EfW plants often encounter difficulties in identifying and managing contaminants within incoming waste streams. For example, items such as a laughing gas bottle or other hazardous objects can cause operational disruptions, increase costs, and reduce efficiency. Limited data and visibility can make it challenging for facilities to proactively address these issues and ensure that suppliers deliver waste streams that meet required standards.

How Wasteer Fixes This

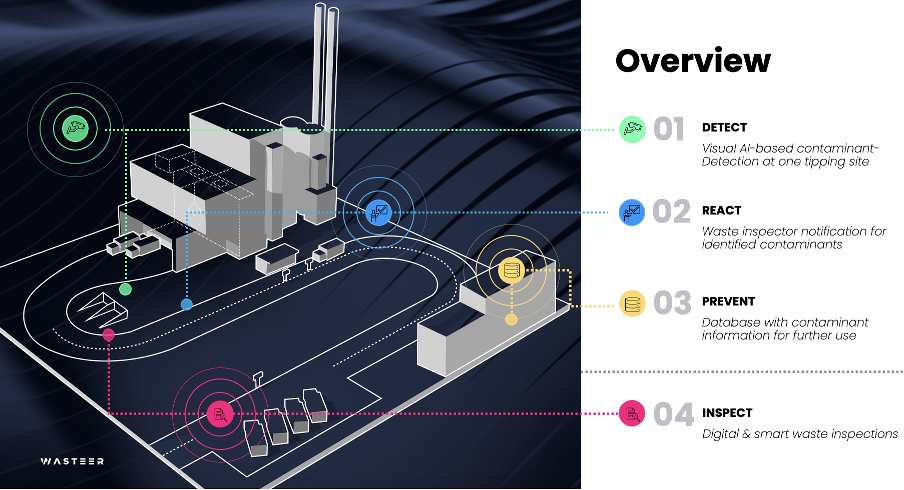

Wasteer offers a way to bridge this gap by providing real-time contaminant detection technology at critical points in EfW plants. This system ensures that, with every unloaded truck, operators gain immediate insights into the presence of contaminants. By addressing potential issues before they escalate, Wasteer enables plants to decrease downtime by up to 30%, increase throughput by up to 2%, and reduce operational costs by up to 8%.

Beyond detection, Wasteer’s technology delivers detailed data about contaminants, allowing operators to trace issues back to specific waste streams and suppliers. This transparency helps plants refine processes, improve accountability, and maintain compliance with regulatory standards.

For example, when a truck unloads, our system identifies the customer using license plate detection, analyses the unloaded waste image by image, and issues a real-time warning to the crane operator if a contaminant is detected. The entire incident is documented in our system, providing a comprehensive record that can be used to hold the responsible party accountable.

Overview of Wasteer’s offerings.

Real-World Examples

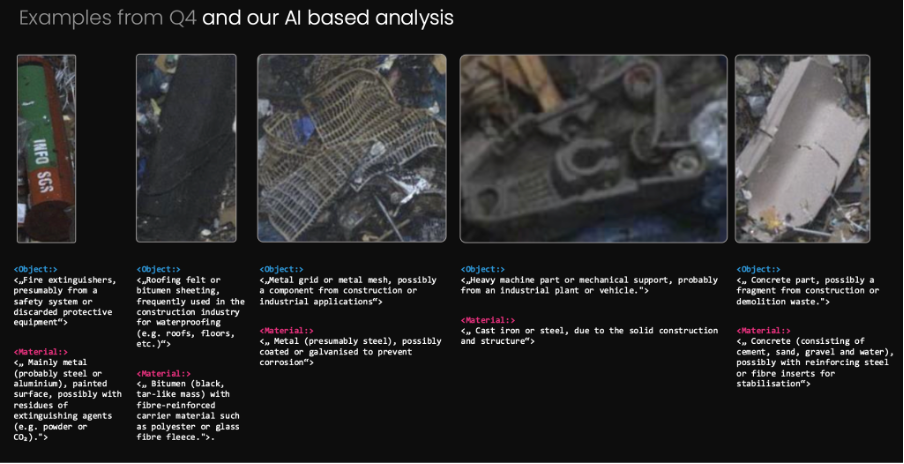

In the last quarter, Wasteer’s technology demonstrated its ability to adapt to the unique needs of different plants by detecting a wide range of contaminants across various materials. From metal grids and concrete fragments to roofing felt and fire extinguishers, the system consistently delivers an unparalleled level of analysis. It provides details as precise as the readable lettering on the extinguishers, tailoring its insights to each facility’s specific requirements.

This adaptability goes beyond detection. The system is designed to evolve with new challenges. For example, if an emerging issue like laughing gas bottles arises, the model can be swiftly adjusted to identify and address it. This combination of precision, flexibility, and responsiveness ensures Wasteer can support plants with diverse waste streams while providing actionable insights to enhance operations.

Examples of contaminant detections made in several plants in Q4 2024.

Why It Matters

Gaining deeper insights into waste streams is more than just an operational improvement; it’s an opportunity to run facilities more efficiently and sustainably. With advanced detection systems, EfW plants can minimize disruptions, lower costs, and take a proactive role in supporting a circular economy.

Written by Benedict von Spankeren, CEO and founder of Wasteer.

For additional questions, please contact Hendrik De Paepe, Sales Manager at hendrik.depaepe@wasteer.de.

Wasteer are an official sponsor for the 2025 Energy from Waste Conference, taking place in London on 5-6 March. Find an exclusive EfW Network discount code here!

Please sign in or register for FREE

If you are a registered user on Energy from Waste Network, please sign in