Introduction

The global energy and waste management sectors are converging at a pivotal moment in the fight against climate change. Municipal Solid Waste to Energy plants, long recognized for their dual role in energy recovery and landfill diversion, are now being reimagined as carbon mitigation assets through the integration of Carbon Capture and Storage (CCS) systems. The Sharjah Waste-to-Energy (WtE) facility in the United Arab Emirates (UAE) is at the forefront of this transition, representing one of the region’s first initiative to couple Waste-to-Energy generation with permanent carbon capture and storage.

This article explains the conceptual framework, technical basis, and broader strategic implications of implementing CCS at the Sharjah WtE facility, highlighting how such a project could deliver both avoided emissions and verifiable carbon removals while supporting the UAE’s Net Zero 2050 ambitions.

Background: Sharjah Waste-to-Energy

The Sharjah Waste-to-Energy facility, a joint initiative between Bee’ah and Masdar, is the first commercial-scale plant of its kind in the UAE. Commissioned in 2022, it processes approximately 300,000 tonnes of non-recyclable municipal solid waste annually, generating around 30 MW of renewable baseload electricity.

The facility plays a central role in Sharjah’s ambition to achieve zero waste to landfill, an ambitious target that has already placed the Emirate at the forefront of waste management innovation in the Middle East. By diverting non-recyclable municipal and industrial residues from landfill, the plant not only generates energy but also prevents landfill potent greenhouse gases emissions.

The next step, however, is to integrate the CCS by transforming the Sharjah WtE facility into a Net-zero energy producer.

The CCS Concept for Sharjah WtE

A preliminary concept study indicates that the Sharjah WtE facility could capture over 400,000 tCO₂ per year from its current Phase-1 operation. With the commissioning of Phase-2, this figure could more than double to 800,000 tCO₂ per year. The captured CO₂ is estimated to be 45% biogenic (from paper, food, and green waste) and 55% fossil-derived (from plastics and other synthetic materials). This split enables both avoided emissions (fossil share) and certified carbon removals (biogenic share), delivering a unique mitigation profile that combines energy recovery, landfill diversion, and negative emissions.

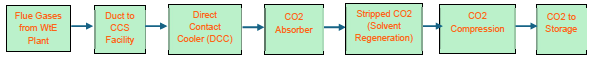

Typical Carbon Capture and Storage Process

Technical Approach

The integration of CCS into a WtE facility requires careful alignment of combustion, flue gas treatment, and downstream capture technologies. At Sharjah WtE, the following process pathway has been studied

(1) Flue Gas Preparation – The existing Waste-to-Energy flue gas treatment line (semi-dry lime absorber, activated carbon injection, and baghouse filter) ensures that the gas stream is already free of particulates, acid gases, and heavy metals—providing an excellent baseline for CO₂ capture integration.

(2) CO₂ Capture Technology – Post-combustion capture using amine-based solvents is the most suitable option for the Sharjah WtE facility. This technology is commercially mature and wellsuited to the relatively diluted CO₂ stream (~10–15% concentration) typical of WtE flue gases.

(3) Compression & Dehydration – Captured CO₂ must be compressed to pipeline pressure and dehydrated to avoid corrosion and hydrate formation.

(4) Transport & Storage – The study considers transporting the compressed CO₂ to depleted gas fields operated by the Sharjah National Oil Corporation (SNOC). Geological storage in these formations provides the potential for secure, permanent sequestration.

(5) Integration with Plant Operations – Heat recovery from the WtE process can partially offset the energy penalty of solvent regeneration, improving the capture efficiency. The integration will be staged to ensure minimal disruption to ongoing operations.

Projected Climate Benefits

When implemented, CCS at Sharjah WtE would directly contribute to the UAE’s Net Zero 2050 Strategy by:

- Delivering a scalable CCS pathway aligned with national industrial decarbonization priorities.

- Demonstrating biogenic CCS as a credible and certifiable route to Net-zero emissions.

- Supporting compliance with international trade frameworks such as the EU Carbon Border Adjustment Mechanism (CBAM).

- Positioning the UAE as a regional frontrunner in linking waste management, renewable electricity, and carbon storage at commercial scale.

In total, the project could mitigate or permanently remove the equivalent of 800,000 tonnes of CO₂ per year once Phase-2 is operational.

Alignment with UAE Net Zero by 2050 Targets

Under the UAE’s Net Zero by 2050 strategy, CCS is identified as a key pillar for decarbonizing hard-to-abate sectors such as power, industry, and oil and gas. The national pathway targets Flue Gases from WtE Plant Duct to CCS Facility Direct Contact Cooler (DCC) CO2 Absorber CO2 Compression Stripped CO2 (Solvent Regeneration) CO2 to Storage the capture of around 10 million tonnes of CO₂ per year by 2030, supported by ADNOC’s largescale projects and new federal legislation promoting CCUS deployment. The government envisions expanding these capacities toward mid-century as part of a broader mix of clean energy, efficiency, and nature-based removals to achieve net-zero emissions.

The Sharjah WtE facility supports this vision by reducing emissions through planned displacement of at least 400,000 tonnes of CO₂, which help UAE move toward its goals of netzero emissions by mid-century.

Challenges and Considerations

While the technical and climate case is strong, several challenges must be carefully managed:

- Energy Penalty: CO₂ capture consumes steam and electricity, reducing the net power output by 35–40%. This trade-off must be balanced against climate benefits.

- Cost: CCS remains a capital intensive. The project will likely require blended financing government grants, carbon credit revenues, and potential international climate funds.

- Regulation: Robust measurement, reporting, and verification (MRV) frameworks are needed to certify removals, especially the biogenic fraction.

Broader Strategic Implications

The Sharjah WtE CCS initiative is more than a single project; it could become a blueprint for the entire Middle East region.

- Replicability: Similar WtE projects in Dubai, Abu Dhabi, and Oman could adopt CCS retrofits, scaling negative emissions across the GCC.

- Regional Hub Potential: Leveraging depleted gas fields across the UAE and wider Gulf could establish a carbon storage hub, integrating multiple industrial emitters.

- Global Leadership: By linking waste management, energy recovery, and CCS, the UAE positions itself at the cutting edge of sustainable infrastructure aligned with COP28 outcomes that emphasized CCS deployment.

Conclusion

The integration of CCS into the Sharjah Waste-to-Energy facility represents a transformational opportunity for the UAE and the wider region. It addresses three urgent needs simultaneously: sustainable waste management, low-carbon electricity generation, and large-scale CO₂ mitigation, including verified negative emissions.

As the World seeks practical pathways to Net-zero, projects like this showcase how existing infrastructure can be re-engineered to deliver outsized climate benefits. If successful, Sharjah WtE with CCS could stand as among the first operational examples of Waste-to-Energy with permanent carbon storage, a milestone of global significance

Please sign in or register for FREE

If you are a registered user on Energy from Waste Network, please sign in